Inkjet has matured into a reliable, versatile platform. But its real potential lies in the emerging technologies that push it into new realms: nanotechnology, precision optics, and hybrid processes that blur the lines between printing and manufacturing. At IPI, the emerging technologies track showcases how researchers and companies are extending inkjet into areas once considered out of reach.

BEYOND THE DROPLET: REDEFINING DEPOSITION

Traditional inkjet relies on droplets in the 1-10 picolitre range, optimized for smooth films and patterned graphics. But many emerging applications require either much finer resolution – sub-micron patterning for displays and electronics – or entirely new material classes such as nanocrystals, conductive pastes, and biological particles. Meeting these demands means rethinking droplet formation itself.

Scrona, for example, is leveraging electrohydrodynamic jetting to go beyond piezo limitations. By using electric fields to draw fluid, rather than pressure waves to push it, EHD achieves feature sizes and viscosities unattainable with conventional systems. This not only expands material compatibility but also opens new scaling paths through MEMS-based multinozzle arrays. Scrona’s approach shows how EHD jetting opens applications for electronics and optics that need finer features and thicker materials.

12 November 2025, 17:15: “EHD-Enabled Inklogic Printheads for Multinozzle Processing of Inks With the Viscosity of Honey” by Dr Patrick Galliker, Scrona

Another breakthrough comes from Hummink, represented by Frédéric Raynal, VP of Business Development. With a PhD in Electrochemistry and over 25 years of experience in the semiconductor industry, Frédéric specialises in advanced manufacturing technologies and drives strategic growth at Hummink.

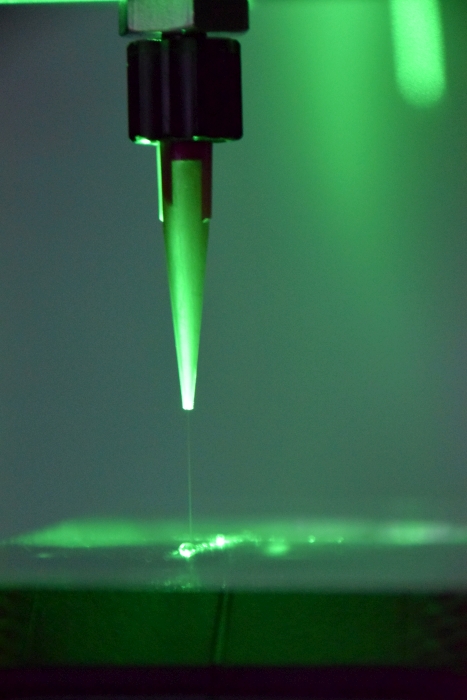

Hummink’s High Precision Capillary Printing (HPCaP) technology redefines printing at the micron scale by leveraging capillary forces and resonance, eliminating the need for external energy sources such as UV, lasers, or pressure. Inspired by Atomic Force Microscopy (AFM), HPCaP employs a glass micropipette attached to a macro-resonator oscillating at controlled frequencies. This mechanism enables precise material deposition with resolutions from 50 μm down to 100 nanometres, adapting seamlessly to substrate topography in real time. Unlike conventional inkjet printing, HPCaP relies solely on capillarity, allowing the deposition of a wide range of materials - including high-viscosity polymers, conductive inks, and biomaterials.

Its ability to print high-aspect-ratio structures and fine interconnects makes it ideal for semiconductor packaging, display repair, biosensors, and even watchmaking. With sub-micron accuracy, adaptability, and compatibility with numerous inks, HPCaP stands as a versatile and sustainable solution for next-generation manufacturing challenges.

12 November 2025, 11:20: “High Precision Capillary Printing: A Technology for Next-Generation Manufacturing” by Dr Frédéric Raynal, Hummink.

Visitor takeaway: Emerging jetting principles are redefining deposition, enabling inkjet to work with new materials and at resolutions once out of reach.

DISPLAYS: THE RACE TO SUB-10 µM

Few sectors push resolution harder than display manufacturing. OLED, MicroLED, and quantum-dot LED technologies all require ultra-precise deposition of nanomaterials. Today, state-of-the-art inkjet printing achieves around 300 ppi — but next-generation displays demand sub-10 µm features.

Dr Manuel Gensler, Research Manager at Fraunhofer Institute for Applied Polymer Research (IAP) presents how EHD-jet printing of cadmium-free quantum dots enables this leap. By formulating stable inks of InP/ZnSe/ZnS nanocrystals and refining jetting waveforms, Fraunhofer has demonstrated pixel-level definition beyond evaporation’s limits. The addition of hybrid organic-QD layers improves electroluminescent efficiency, showing a clear path toward industrial adoption. His results highlight how quantum-dot inks give display makers a practical digital path to next-gen OLED and MicroLED displays.

12 November 2025, 11:45: “EHD-Jet Printing of Quantum Dots: Ink Formulation and Process Development for sub-10 mm High-Resolution Displays” by Dr Manuel Gensler, Fraunhofer IAP.

Visitor takeaway: Advances in sub-micron inkjet deposition are bringing digital printing into the core of next-generation display manufacturing.

NANOMATERIALS: GENTLE HANDLING AT SCALE

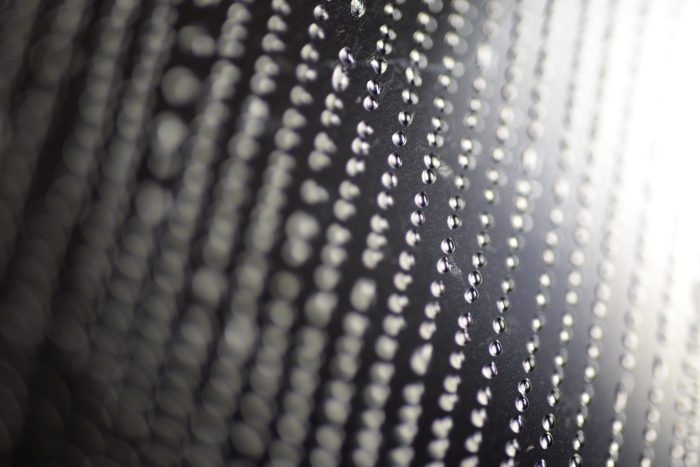

Another frontier lies in printing fragile nanomaterials. Conventional aerosol-jet and inkjet methods often damage delicate structures due to pressure, heat, or prolonged ultrasonics. Dr Andreas Winkler, Co-Founder at Sonojet introduces surface acoustic wave aerosol generation as a solution. By using pulsed SAWs to atomize inks under mild conditions, materials from 0D nanocrystals to 2D flakes can be deposited without aggregation or degradation. The result: scalable, nozzle-free printing compatible with advanced materials. His work proves manufacturers can scale nanomaterial printing without damaging fragile structures – a key step for electronics.

Image courtesy Sonojet

Image courtesy Sonojet

12 November 2025, 12:10: “Surface Acoustic Wave Aerosol Printing for Nanomaterial Deposition” by Dr Andreas Winkler, Sonojet.

Visitor takeaway: Gentle aerosol generation opens the door for scalable, nozzle-free printing of advanced nanomaterials.

Beyond materials handling, inkjet is also converging with broader themes like sustainability and healthcare.

SUSTAINABLE ELECTRONICS AND HEALTHCARE

Emerging technologies are also about convergence with sustainability and health. Profactor’s Researcher Maximilian Scherf demonstrates multi-material inkjet for eco-PCBs, medical devices, and air-quality sensors. By combining conductors and dielectrics in a single workflow, fully printed systems become possible — from wearable vital-sign monitors to biodegradable sensor platforms. His demo shows how eco-PCBs align performance with sustainability, helping OEMs meet regulatory and environmental targets.

12 November 2025, 12:35: “Advancements in Multi-Material Inkjet Printing of Functional Materials for Sustainable EcoPCBs, Medical Devices and Air Quality Sensors” by Maximilian Scherf, Profactor.

Prof. Claas Willem Visser, Co-founder and Chief Scientific Officer (CSO) of IamFluidics adds a complementary perspective with in-air microfluidics. By forming and solidifying droplets mid-flight, functional particles and fibres can be fabricated at 10-100x the throughput of chip-based microfluidics. This opens scalable production of pharmaceuticals, energy storage particles, and bio-inspired materials. His work demonstrates scalable production methods that could speed up pharmaceuticals and energy storage.

Image courtesy IamFluidics

Image courtesy IamFluidics

12 November 2025, 14:30: “Inkjet Printing of Functional Particles via In-Air Microfluidics” by Prof. Claas Willem Visser, IamFluidics.

Visitor takeaway: Convergence with sustainability and healthcare shows how inkjet enables fully printed electronics, medical devices, and new material platforms.

OPTICS AND PHOTONICS

Inkjet is also entering precision optics. At Morphotonics, Bram Titulaer, Co-Founder & Chief Product Officer integrates inkjet into roll-to-plate nanoimprinting, enabling tuneable residual layers for AR waveguides. His work shows AR optics can now be fine-tuned with digital precision.

12 November 2025, 16:25: “Inkjet-Enhanced R2P Nanoimprinting: Scalable Precision for Next-Gen AR Waveguides” by Bram Titulaer, Morphotonics.

Dr Qihao Jin, Founder & CTO at Prio Optics highlights direct inkjet deposition of optical coatings, filters, and light-modulating surfaces – an additive alternative to costly vacuum processes. His insight highlights how inkjet reduces cost and complexity compared to traditional vacuum deposition in optics.

12 November 2025, 16:50: “How Can Inkjet Printing Contribute to Precision Optics?” by Bram Titulaer, Morphotonics.

Visitor takeaway: Inkjet is becoming a key tool for optics, offering cost-effective, additive alternatives to traditional processes.

EXPANDING THE DEFINITION OF PRINTING

Taken together, these advances redefine what “printing” means. Droplets are no longer limited to pigments on paper; they are carriers of function, structure, and performance. At IPI, the emerging technologies track shows how inkjet is evolving into a platform for additive manufacturing at the micro- and nanoscale.

Visitor takeaway: Emerging technologies show that inkjet is no longer limited to graphics – it is evolving into a platform for additive manufacturing at the micro- and nanoscale.

See the complete IPI 2025 programme and plan your track.