Viscosity has long defined the boundaries of inkjet technology. For decades, piezoelectric printheads have been optimized to jet fluids in the range of 8-25 mPa·s. That range has enabled remarkable growth in graphics, textiles, packaging, and even some functional printing. Yet, entire industries remain out of reach because their materials – adhesives, coatings, paints, resists – are simply too thick. The future of inkjet depends on breaking this viscosity barrier.

WHY VISCOSITY MATTERS

Viscosity is not just a number. It is the expression of a fluid’s resistance to flow, shaped by its molecular structure and interactions. High-viscosity fluids tend to carry functional payloads – polymers, nanoparticles, conductive fillers, or resins – that enable electrical, optical, or structural performance. But these same properties make them difficult to jet: they resist acceleration, risk clogging, and require careful control of surface tension and nozzle geometry.

For industrial production, this is a critical limitation. Manufacturers who rely on screen printing or dispensing have access to a much wider viscosity window, which allows them to work with richer and more functional formulations. If inkjet is to challenge these incumbent processes, it must stretch far beyond its comfort zone.

NEW TECHNICAL APPROACHES

One of the most ambitious steps forward comes from Quantica, whose new print engine is designed to reliably deposit materials with viscosities an order of magnitude higher than traditional piezo inkjet – up to 250 mPa·s. Ben Hartkopp, Founder and Andreas Müller, Head of System Integration demonstrate how this opens pathways for adhesives in electronics, insulating layers in e-motors, and functional coatings in battery systems. By doing so, inkjet not only competes with screen printing but surpasses it, offering digital flexibility and reduced waste. Their work shows how handling up to 250 mPa·s enables new industrial uses – from adhesives in electronics to functional coatings in batteries – giving OEMs digital flexibility where screen printing once dominated.

12 November 2025, 16:25: “Functional Inkjet for Ultra-High Viscosity Materials: Advancing Industrial Production” by Ben Hartkopp and Andreas Müller, Quantica

Fraunhofer Institute for Manufacturing Engineering and Automation (IPA) adds another angle: examining the transfer of screen-printable materials into the inkjet domain. Antonia Götz, Doctoral Student highlights the process and technological challenges that arise – from adapting rheological profiles to modifying waveform strategies. The promise is significant: if inkjet can handle the same materials as screen printing, the digital advantages of on-demand, form-free production become immediately accessible to markets still reliant on manual processes. Her perspective shows how adapting rheology and waveforms helps industries still dependent on screen printing tap into inkjet’s digital speed, reduced waste, and on-demand flexibility.

Image courtesy of Quantica

Image courtesy of Quantica

12 November 2025, 16:50: “Inkjet Printing of Screen Printing Materials: Technological and Process-Related Challenges” by Antonia Götz, Fraunhofer IPA

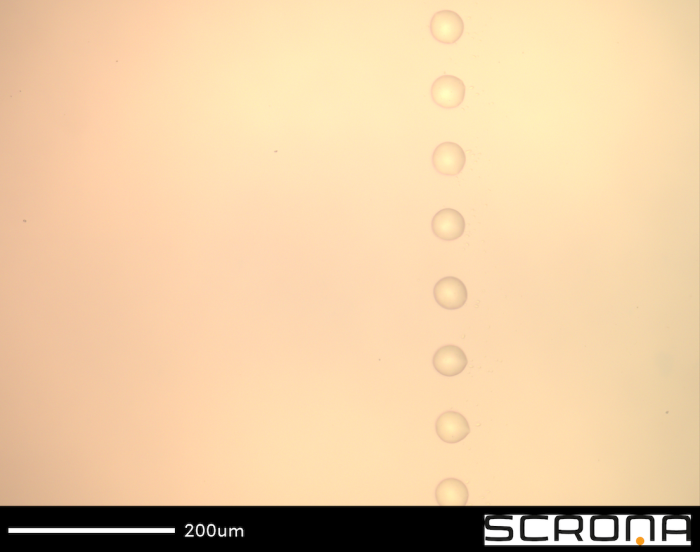

Scrona takes an entirely different approach. By reviving electrohydrodynamic (EHD) jetting, Dr Patrick Galliker shows how MEMS-based printheads can bypass many of the rheological limits that restrict piezo systems. With EHD, even honey-like fluids – in the 10 Pa·s range –can be precisely deposited without heating. The technical hurdle shifts from viscosity management to charge control and jet stability, opening a new technological pathway altogether. Scrona’s approach shows how EHD jetting enables OEMs to enter electronics and optics applications that demand finer features and thicker materials.

12 November 2025, 17:15: “EHD-Enabled Inklogic Printheads for Multinozzle Processing of Inks With the Viscosity of Honey” by Dr Patrick Galliker, Scrona

Visitor takeaway: This breakthrough means industries like electronics, automotive, and energy can now consider inkjet for materials traditionally restricted to screen or dispense systems.

Ink Manufacturer: Loctite, Product: Loctite Ablestik 8387B, Viscosity: 9500 mPa.s (cP). Image courtesy of Scrona.

Ink Manufacturer: Loctite, Product: Loctite Ablestik 8387B, Viscosity: 9500 mPa.s (cP). Image courtesy of Scrona.

IMPLICATIONS FOR THE INDUSTRY

Breaking the viscosity barrier is not only about expanding material options. It fundamentally reshapes the economics of production. Screen and pad printing, despite their material flexibility, are labor-intensive and less suited to short runs or personalization. Inkjet, with its digital workflow, is inherently adaptable – but only if it can handle the same functional materials.

By extending viscosity ranges, inkjet bridges this gap. It becomes not only a graphics tool but a true industrial deposition method, capable of laying down adhesives, conductive pastes, resists, and protective coatings. For OEMs, this unlocks entirely new verticals. For end-users, it promises faster turnaround, lower waste, and the ability to tailor products without costly setup.

Visitor takeaway: Extending the viscosity range reshapes production economics, making inkjet a viable alternative to screen and pad printing in electronics, energy, and automotive sectors.

THE NEXT PHASE

IPI’s high-viscosity track highlights how inkjet is pushing beyond its traditional boundaries. Advances in piezo engineering, adaptation of screen-printing formulations, and alternative methods such as EHD show that the viscosity frontier is steadily expanding. These developments do not yet replace established processes like screen or dispense printing, but they open new possibilities where digital flexibility and reduced waste offer clear advantages.

As the ability to handle higher-viscosity materials matures, inkjet’s role in manufacturing, electronics, energy, and automotive sectors is likely to grow – not as a wholesale replacement, but as a complementary production tool that broadens the range of viable applications.

Visitor takeaway: High-viscosity jetting represents a significant step forward, extending inkjet’s capabilities into new industrial domains while complementing incumbent technologies.

See the complete IPI 2025 programme and plan your track.